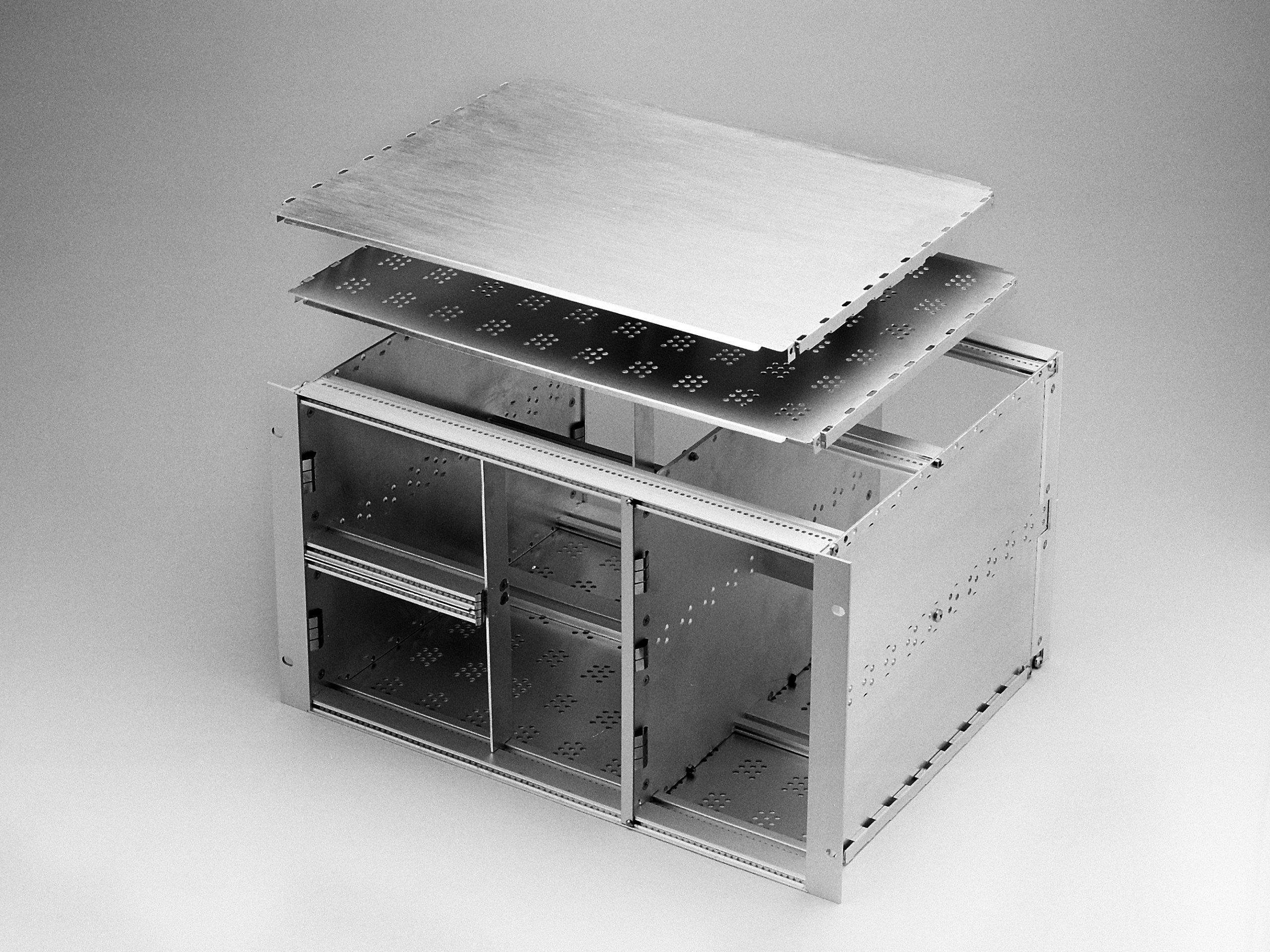

Versirak has been designed to accept plug-in modules and printed circuit boards. Compatible with 19″ practice, externally conforming to DIN 41494 parts 1 and 5, internally conforming to DIN 41494 part 2. The system has been designed to provide a level of EMC which can be achieved on an upgrade basis without the need to dismantle any of the original structure.

Sideplates are made from 2.5mm aluminium alloy, Horizontal rails and Mounting angles made from extruded aluminium alloy. Sideplates and Horizontal rails are protected using a conductive surface finish, iridite NCP, the Mounting angles are non-conductive, satin anodised. Flush mounting bushes enable the Mounting angle to be fitted front or rear independently of the rails and provides earth continuity. The Sideplates are punched on a 30.00mm pitch along the depth for variable rail fixing positions with semi-shear indents to prevent rail rotation, plus M5 single screw fixing each end. Horizontal rails which accept guide rails are pierced on a 5.08mm pitch for location and are printed along the inner face 1-84 and 84-1 to ease guide rail alignment.

Supplied in kit form. Assembly and earth continuity testing can be carried out on request.

Available as a 3U subrack, 6U subrack and 9U subrack – Plus accessories.